Engine Management system for Audi vehicle V6 engine

What is engine management system for audi?

Engine management system is a system in which an engine parameters are controlled electronically through different sensors and actuators to get optimum performance from the engine. Running a vehicle on less fuel and tune is for optimum performance is the key requirement for any modern engine. Consuming less fuel and burning the fuel totally in the engine to protect environment is the second achievement of the engine management system.

Types of sensors used for audi engine management system

There are two main types of sensors used on audi v6 engine for engine management system

They are input sensors and output actuators

Input sensors are collecting different parameters data like air quantity, air temperature, air flow, engine rpm, crankshaft position, camshaft position, coolant temperature, Oxygen quantity in exhaust gases and engine knock data etc.

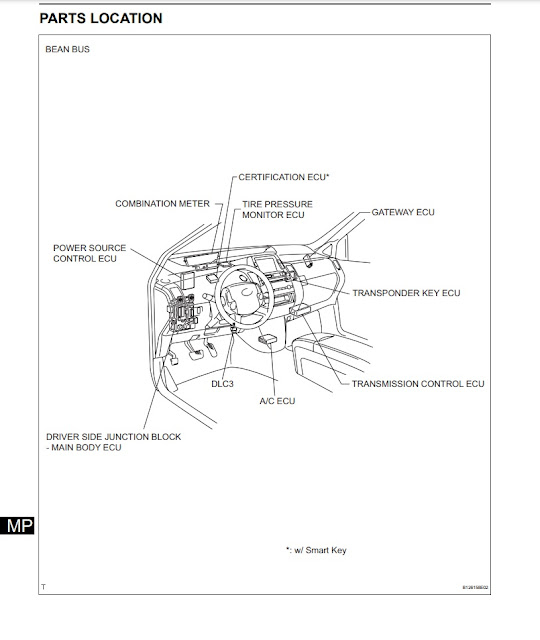

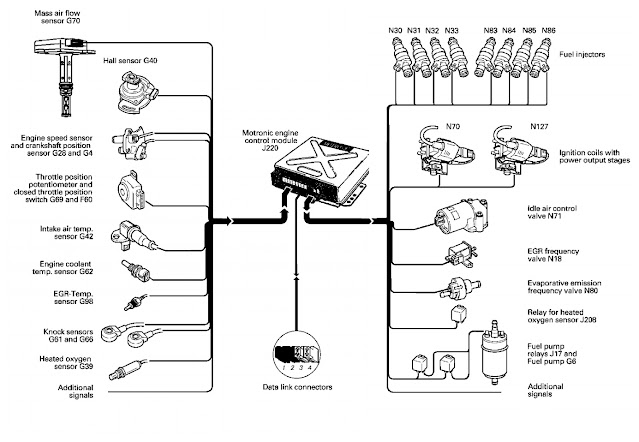

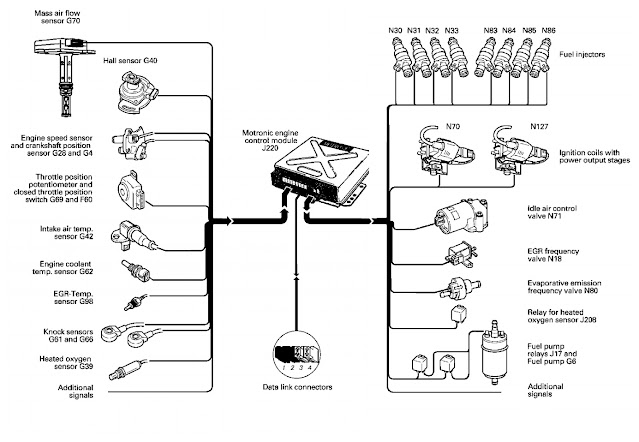

The output actuators are controlling different quantities and parameters according to requirement and for best performance achievement. Such quantities are air, fuel, spark, oil, exhaust gas and many others. All sensors and actuators are connected to the engine computer or ecu which accepts data from different sensors and sending control signals to different sensor for optimum control and best resource utilization. following is a simple block diagram of a typical audi engine control system used on audi v6 engines.

|

| Audi v6 engine management system |