What is a Circuit Breaker? Vacuum circuit breaker working function

What is a circuit breaker?

A circuit breaker is an electrical device that is used to interrupt electrical power. A circuit breaker is like a heavy switch that is used to switch on and off heavy electrical power. A special arrangement is made to quench the arc produced between switching contacts during circuit interruption. For the purpose of arc quenching, air, sf6 gas, or vacuum is used in the circuit breaker.

Types of circuit breaker

A circuit breaker is categorized in many ways. Different types of circuit breakers are used according to needs and requirements.

Circuit breaker types according to voltage

LV circuit breaker

LV circuit breaker is used on low voltage to interrupt electrical power. Air is normally used as arc quenching media in such kind of circuit breakers.

MV circuit breaker

MV circuit breakers are used to interrupt medium voltage in industry and power distribution substations. Vacuum and oil are used as arc quenching media in such kind of circuit breakers.

HV circuit breaker

HV circuit breakers are used to interrupt very high voltage power. SF6 gas is used as quenching media in such kind of circuit breakers.

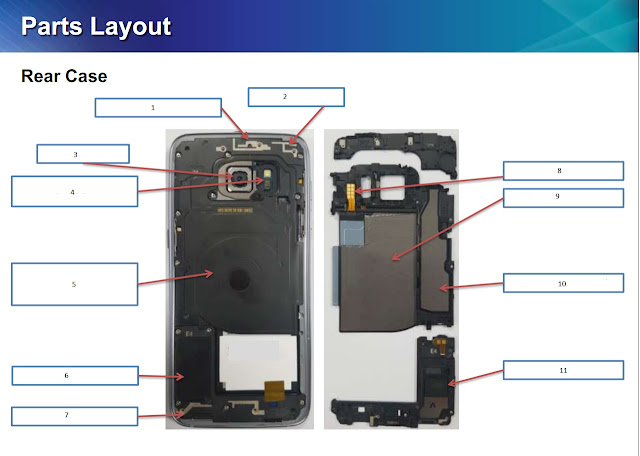

Parts of Circuit breaker

There are many parts of a circuit breaker. A circuit breaker is a piece of complex electrical equipment having many parts like contacts, springs, levers, hinges, and many other parts. The following diagram shows common parts for a circuit breaker.

|

| Circuit breaker parts |

- The Charging mechanism of the gearbox

- The Charging flange

- The Driver

- The Spring charging motor

- The Limit switches

- The Manual spring charging port

- The Close pushbutton

- The Close coil 52SRC

- The Open pushbutton

- The trip coil 52T

- The Closing spring charge indicator

- The Linkage

- The Control lever

- The Close-open indicator

- The Operation counter

- The Operator housing

- The Shock absorber

- The Closing spring

- The Charging shaft

- The Crank

- The Cam disc

- The Lever

- The Pawl roller

- The Close latch pawl

- The Drive lever

- The Trip free coupling rod

- The Spring return latch

- The Trip free coupling lever

- The Jackshaft

- The Lever - phase C

- The Lever - phase B

- The Lever - phase A

- The Opening spring

- The Auxiliary switch

- The Auxiliary switch link

3 phase power and 3 phase power generator

3 phase power and 3 phase power generator

3 phase power generator

3 phase power generator is a machine which generates 3 phase ac power. AC power is of two types. One is single phase and the other is multi phase. 3 phase is example of multi phase power which is very commonly used due to its special characteristics and powerful nature over single phase ac power. 3 phase power is generated in the same way as single phase power is generated. Only difference is the construction of 3 phase ac power generator. There are three seperate windings 120 degree apart each other. In a 3 phase power generator 3 windings are places 120° apart to make a complete machine having 3 separate windings in total of 360°.

RMS value of a sin wave signal

|

| Sin wave graphical presentation |

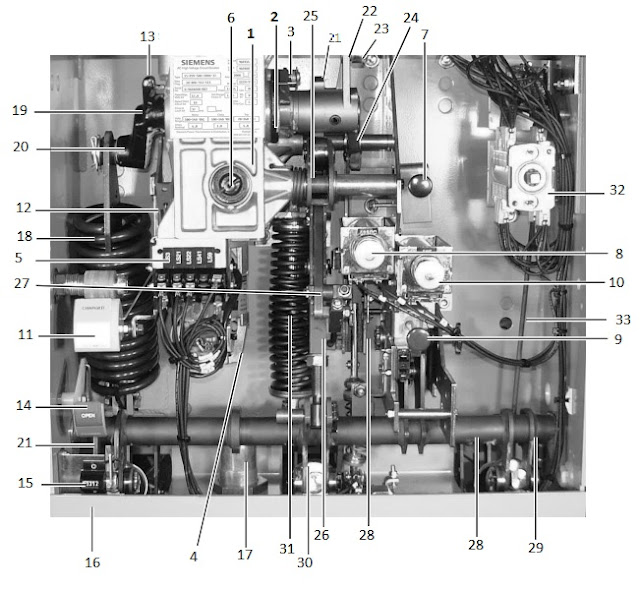

3 phase power generation

|

| 3 phase power generation |

Components of three-phase squirrel cage induction motor. Starting method.

Components of three-phase squirrel cage induction motor to determine starting method

Parts of squirrel cage induction motor

- Motor body or frame

- Stator

- Rotor

- Stator winding

- Stator core

- End covers

- Cooling fan

- Bearings

- Dust seals

- Terminal box

- Terminals

- Spacers

- Rotor short-circuiting rings

- Rotor bars

- Motor nameplate

- Stator cooling fins

- Mounting bolts

Motor body or frame

Stator

Rotor

Stator windings

Stator core

End covers

Cooling fan or cooling disk

Bearings

Dust seals

Terminal box

INVEREX FRONIUS SYMO 5.0 & 20.0 KW

Inverex FRONIUS SYMO 5.0 & 20.0 KW

Inverex Fronius Symo series is the 3 phase inverter series for large power requirements. Inverex Fronius Symo power ranges from 5KW to 20KW. Inverex Fronius Symo produces three-phase pure sine wave power which could be used as an alternative to the line three-phase power. Inverex Fronius Symo uses the standard interface of LAN Ethernet and WLAN WiFi for easy interfacing and control. Fronius Symo provides the best meter interface which shows very clear information of the energy consumption from different sources like Utility, Solar, and Battery. Also, the interface provides important data to user which helps the user to manage parameters.

|

| Inverex fronius symo 5.0 20KW |

Audi rear wheel leaf spring for suspension

Audi rear wheel suspension leaf spring

Audi rear wheel spring diagram:

|

| Audi rear wheel suspension spring |

Audi rear wheel spring components details:

- Rear spring shackle

- Bush

- Bush

- Washer

- Nut

- Rear spring shackle

- Washer

- Nut

- Bush No. 2

- Rear spring assembly

- Bolt

- Rear spring bumper

- U bolt

- Washer

- Nut

- Spring U bolt seat S/ A

- Bush

- Nut

- Bolt

Audi car rear wheel suspension components detail diagram and illustration

Audi rear wheel suspension components diagram

Illustration:

|

| Audi rear wheel suspension diagram |

Components details and description:

- Bush

- bush

- Rear spring shackle

- Rear spring shackle

- Bush No. 2

- Rear spring assembly

- U bolt

- Rear spring bumper

- Spring U bolt seat S/ A

- Washer plate

- Cushion

- Washer plate

- Cushion

- Washer plate

- Rear Shock absorber

- Washer plate

- Bush

- Washer plate

- Actuator

- Dust seal

- Bracket

- Washer plate

- Rear-axle housing

- Rear-axle bearing retianer

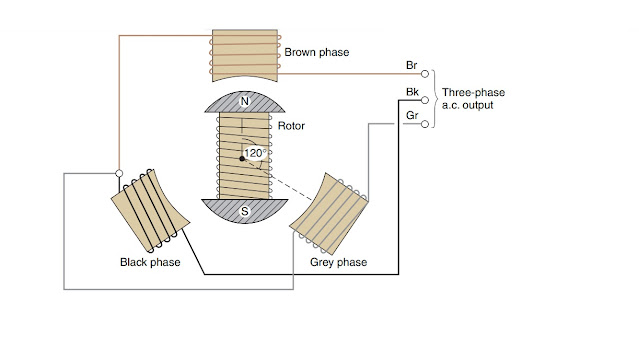

The Manual transmission for manual car

The manual transmission used in manual cars

The manual transmission schematic diagram and illustration:

|

| The manual transmission used on manual car |

Components details for manual transmission used on most manual cars:

- Shift lever knob

- Snap ring hole

- Shift lever ball seat

- Shift lever boots

- Shift lever ball seat

- Bush

- Shift lever Ay

- Hose

- Clamp

- Union

- Bolt

- Hanger

- 5th Shift arm pivot

- Shift interlock No. 1 pin

- Shift interlock No. 2 pin

- Clamp

- Back-up lamp switch

- Clamp

- Clamp

- Tight plug

- Mission case cover gasket

- Torsion spring

- Shift fork lock plate S/ A

- E ring

- Ball

- Compression spring

- Gasket

- Reverse restrict pin holder

- Transmission case cover

- Slotted pin

- Shift inner lever

- Shift lever shaft

- Snap ring shaft

- Reverse restrict pin

- Torsion spring

- Shift outer lever No. 1

- Shift lever housing bust cover

- 3rd & 4th shift fork

- Ball

- Compression spring

- 3rd & 4th shift fork shaft

- Gear shift head No. 2

- 1st & 2nd shift fork shaft

- 1st & 2nd shift fork

- Shift arm pivot

- Gasket

- Reverse shift arm

- Compression spring

- Reverse shift fork

- 5th & reverse shift fork shaft

- 5th shift head

- 5th shift arm

- Gasket

- 5th shift arm pivot

- 5th shift arm shaft

- 5th shift fork

- Hole snap ring

- Bearing

- Input shaft

- Bearing

- Synchronizer ring No. 3

- Synchromesh shifting key spring

- Synchromesh shifting key

- transmission clutch hub no. 2

- transmission hub sleeve no. 1

- Synchronizer ring No. 3

- Needle roller bearing

- 3rd gear

- Output shaft

- 2nd gear

- Synchronizer ring

- Transmission clutch hub no. 1

- Reverse gear

- Synchronizer ring

- 1st gear bearing inner race

- Needle roller bearing

- 1st gear

- 1st gear thrust washer

- Output shaft rear bearing

- 5th gear

- Conical spring washer

- Look nut

- Bimetal formed bush

- Reverse idler gear S/ A

- Rever Idler gear shaft

- Reverse idler stopper

- Bolt

- Bearing

- Counter gear

- Woodruff key

- Counter gear shaft

- Bearing

- 1st gear thrust washer

- 5th gear bearing inner race

- Needle roller bearing

- countershaft 5th gear

- Synchronizer ring no. 3

- synchromesh shifting key

- Transmission clutch hub no. 2

- Synchromesh shifting key spring

- Transmission hub sleeve no. 1

- Spacer

- Locknut

- Clamp

- Clutch housing

- Type S oil seal

- Transmission case gasket

Honda civic overhead components illustrated diagram, Honda repair service manual

Honda civic overhead components illustrated diagram, Honda repair service manual

Honda Civic and Honda city overhead components illustration

Honda Civic Honda city overhead components details

- Head

- Rocker arm assembly

- Exhaust camshaft

- Intake camshaft

- Exhaust camshaft gear

- Intake camshaft gear

- Camshaft key

- Spark plug well rubber seal

- Headcover gasket

- Camshaft plate

- Camshaft holder

- TDC sensor 1

- TDC sensor 1 O ring

- TDC sensor 2

- TDC sensor 2 O ring

- Camshaft cover bolts

- Camshaft cover bolts washers

- Camshaft cover bolts rubber seal