Manual Push Button Starters vs Automatic Starters

Manual push-button starters are used for fewer numbers of motors or temporary motor running operations. These starters are made with two or three load contacts. Two load contact starters are used for single phase motor starting or DC motor. Whereas the three load contact starters are used for three-phase motors operation. Manual Push-button type starters are made integral and not fractional power size or horsepower size. The two load contact type starters are generally used to control 5 horsepower single-phase motor or 2 horse-power DC or direct current motor. The three-load contacts starter is capable of controlling three-phase motors powered up to 10 horsepower or 7.5KW.

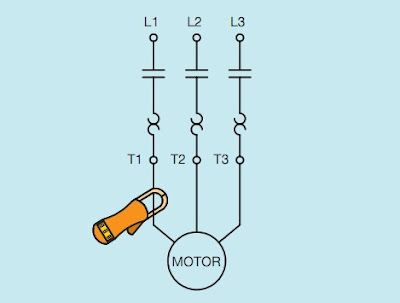

A manual three contacts push-button starter is shown here below.

|

| Manual Push button starter |

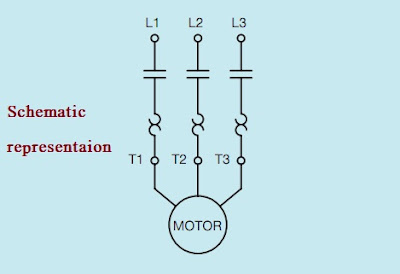

Also, you can see the circuit schematic for such a start below as in industry you will deal with the circuit schematic and not the actual starter drawing.

|

| Manual Push Button Starter Schematic |

In a manual push-button type starter, there are two pushbuttons for a basic type starter. Whereas there are three push buttons for forward reverse starter. One button is for Start other button is for Stop and the third button is for Reverse in case of forward reverse starter.

In this type of starter, the overload is thermal type. Nowadays electronic overload Relays are also common. In case of thermal overload, if any of the phases to the motor draws more current, the bimetal strip attached to it will tilt and will break the current path to the contactor coil which will trip the motor by switching the contactor off. Later the thermal overload or electronic overload can be reset by pressing a reset button on the overload relay. Pressing the reset button resets the mechanism attached to the tripping system of the overload. The function of the buttons is to Start or Stop the motor. There is a seal-type contact on the contactor which is used to hold the motor in the Start condition.