Motor circuit Troubleshooting. Reasons for Motor overloading

Motor circuit Troubleshooting. Reasons for Motor overloading

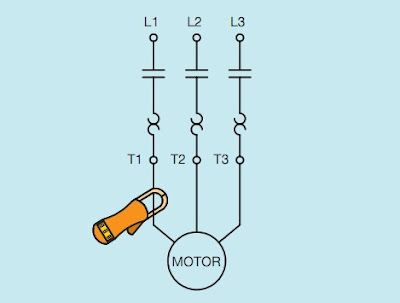

In the process industry motors are used all over. Thousands of motors in the single process industry are not a big number. Such electric motors are used to drive different types of mechanical loads like pumps, fans, belt conveyors, mixers, grinders, or cutters. Mostly Induction motors are used in industry. They can be single-phase or three-phase. Three-phase motors are very common in the industry due to their efficient operation and robust design. In normal conditions motors are running smoothly without giving any trouble. But sometimes when load running conditions are not even, the motors trip on overload. This motor tripping on overload is necessary to prevent the motor from blowing and burning. If the motor is not tripped in case of an overload, the motor takes more current which heats up the motor, and eventually motor burns due to much current consumption. To prevent the motor from such catastrophic burning an overload protection relay is used in the motor circuit. The function of the motor overload relay is to monitor the motor current all the time and trip the motor in case of any overload detected.

|

| Three-phase motor starter circuit diagram |

Now in the case of an overloaded motor, the service technician or engineer must check the motor as well as the motor circuit. There should be no obvious damage to the motor or its circuit. All three phases should available in the case of a three-phase system. In the case of a single-phase motor, it should be confirmed that the phase and neutral both are present. Also, the motor should be checked that there should no restriction to motor rotation. In the case of a small motor, the motor shaft could be rotated with hand along with load connected. But in the case of a very big motor, the motor shaft can't be rotated with a hand. It's a must to confirm motor and load bearings. Sometimes the motor or load bearings are damages due to which the motor is overloaded. Also, the mechanical process load must be evaluated so that there should be no excessive load on the motor. If the load is too much, it is recommended to decrease the load before giving a start to the motor after resetting. At the restart, the motor load current must be checked and measured with the help of a clamp meter. In the case of a single-phase motor only one phase current would be measured. Whereas in the case of a three-phase motor all three-phased would be measured. The motor-rated current could be obtained from the motor nameplate.

|

| motor current measurement |

Comments

Post a Comment